Custom Toll-Blended Process Chemicals

Improve your ROI without sacrificing quality

Treatments and Coatings

From durable coatings to safer and more effective pretreatments, metal treatments are our specialty.

Process chemicals

Reduce wear on tear on equipment, increase manufacturing speed, and keep your workers safe with custom-formulated metalworking fluids and other process chemicals.

Wastewater Treatments

Avoid costly fines and meet your environmental commitments with effective process water treatments.

Fully custom solutions

Don’t see your application listed? We work with each client to produce custom chemistry for almost any industrial use. Talk to a sales agent today to see what we can do for you!

Industries Served

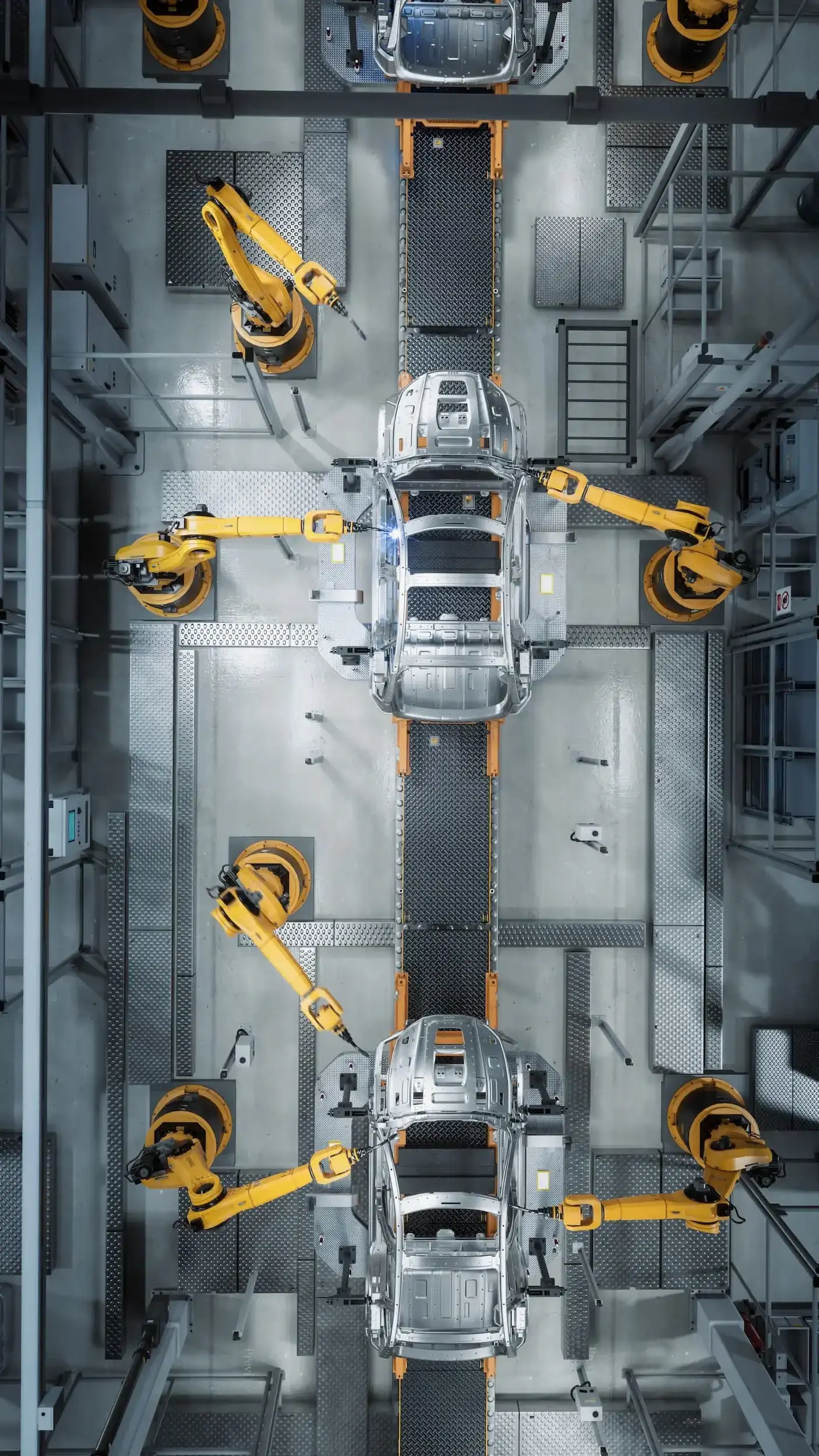

Americo Chemical provides process chemistry for manufacturing businesses across many sectors, including: Transportation and Recreational Vehicles, Construction and Agriculture Equipment, Consumer Goods and Appliances, Industrial Manufacturing. Our products are found in every stage of the manufacturing process in facilities across America. These are our core offerings:

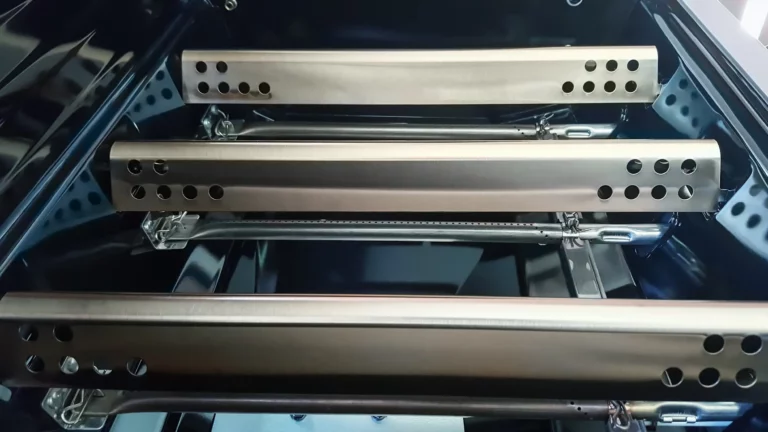

Metal Treatment

The importance of safety and sustainability in manufacturing cannot be overstated. From increasingly stringent government regulations to consumer preference for cleaner, greener products, it’s crucial that your treatments and coatings offer the performance and sustainability features you need. Coatings and metal treatments are at the heart of our service offering. Our custom-engineered coatings are tailored to the unique needs of each facility and process. This high level of customization allows Americo coatings to consistently outperform generic solutions from leading competitors.

Chemical Process

With stringent regulations and the potential for hefty fines for non-compliance, effective wastewater management is a critical component of any manufacturing process. Americo offers innovative chemical solutions to simplify waste management, reduce pollution, and ensure the safety of your workers.

Our products can help clump pollutants for easier cleanup, neutralize hazardous chemicals safely and efficiently, and mitigate health and safety risks associated with wastewater management. By choosing Americo’s custom chemical solutions, you not only ensure compliance with regulatory standards but also protect the environment and your bottom line.

Metalworking Fluids

We rely on a combination of first-hand expertise and data-driven process optimization to find the right custom blend for your business. Our specialty chemicals are found in facilities across America. There’s a good chance that one of our existing blends is well-suited to your requirements. If not, we will work closely with you to find the perfect solution.

Americo’s Innovative Total Systems Approach Delivers Real Value

Are your chemicals getting the job done?

Americo Chemical is committed to a process of continual improvement we call our “Total Systems Approach.” Many chemical providers offer generic solutions or fixate on a single part of the manufacturing process. This limits the value they can provide.

Americo recognizes that each step of your process directly affects the next step. When we work with you, we analyze your processes from beginning to end. Our custom solutions address practical challenges faced by you and your team: overheating equipment, poor cut quality, clogging and spills that slow down production. Only by understanding and addressing your unique challenges can we maximize your ROI.

Americo Chemical is an ISO 9001 certified company, indicating our commitment to and expertise in quality management and optimization. Through our expertise and proven processes, we provide far more value than chemistry alone.

Product Applications

Our custom chemistry is found in manufacturing facilities across America. We work with a wide range of clients across many sectors including:

- Heavy and Light Duty Construction Equipment

- Automotive

- Tractors

- Recreational Vehicle Manufacturing

- Boat Manufacturing

- Conduit and Tubing

- Fitness Equipment

- Agriculture Equipment

- Snow Equipment

- Lawn Equipment

- Appliances – Grills, Refrigerators, Washers, Dryers, etc.

- Electronic Industry

- Outdoor and Office Furniture

- Power Generation

- Architectural

Our agile processes enable us to work with clients of any size. Our advanced blending facility allows us to offer “just in time” manufacture and delivery of most process chemicals. Whether you’re a small facility or a massive outfit, we have the capacity to serve you.

Though we provide a wide range of commodity and custom chemicals for all kinds of manufacturers, our particular specializations include metalworking fluids, metal treatments and coatings, and process wastewater chemistry.

Our Product Specialties

Though we provide a wide range of commodity and custom chemicals for all kinds of manufacturers, our particular specializations include metalworking fluids, metal treatments and coatings, and process wastewater chemistry.

Not sure if we offer what you’re looking for? Ask one of our experts today!

Americo Insights

We employ a consultative process to identify best-fit solutions for each client. Our Total Systems Approach looks at every stage of your process to find and address inefficiencies. If your facility has particularly unique needs, you may be interested in our manufacturing process consulting service.

Process methods for improving manufacturing sustainability

No amount of sustainable practice will undo the effects of climate change, but they can contribute to lower operating costs, more efficient processes, and more...

Enhancing Efficiency with Just-In-Time Chemical Blending and Delivery

Just-in-Time production offers transformative benefits for the chemical sector including better efficiency and more customization options.

Interested in our tailored solutions?

Though we provide a wide range of commodity and custom chemicals for all kinds of manufacturers, our particular specializations include metalworking fluids, metal treatments and coatings, and process wastewater chemistry.